Fixing

Our Future

A vision for the future of Manufacturing in Europe 2030

“Stories bring us together,

untold stories keep us apart.”

– Elif Shafak

Fixing Our Future

Foreword by Klaus Beetz, CEO EIT Manufacturing

The manufacturing industry is a key driver of prosperity, growth, and job sector. The sector also plays a pivotal role in the transformation towards a climate neutral and sustainable circular economy.

Europe has always been in the drivers’ seat for industrial innovation. Today is no exception. EIT Manufacturing was established in 2019, with the objective to mobilize all relevant stakeholders to drive the change towards sustainable production.

Today, EIT Manufacturing has growing into a powerful ecosystem bridging education, innovation and business creation, and bringing together the most innovative ideas to make Europe a role model in remanufacturing and circular economy.

This paper intends to further stimulate the thinking in these area, presenting a compelling vision, together with stories and debates to foster your thinking.

Let’s make sustainable innovation happen!

Why a Vision?

For there to be a future of manufacturing, we first need to ensure that there is a planet to live on. Whereas sustainability and tackling climate change were once ‘something good to do on the side’, they are now at the forefront of global conversation as a necessity to address. Climate change will impact everything, including manufacturing. We are living in a time where uncertainty, complexity and volatility are the new normal. EIT Manufacturing (EITM) recognises that this is a crucial moment of transformation that requires all parts of society, industry, companies, academia and people to move together. Manufacturing included.

There are many unknowns and questions in the mind of manufacturers. For example:

- What will be the new skills needed and what to do with the current skills gaps?

- How do we ensure an inclusive future where new generations of employees are

inspired to shape the future of manufacturing? - How to ensure that a fair human-centred transformation is also a

green transformation? - What will we be producing in a future where resources are limited?

- How to create future-proof factories in 2030, considering people, planet and profit?

“We live in increasingly uncertain times. For many, this is a source of fear; for others, it is a source of inspiration.”

To address these challenges, EITM created an optimistic vision for 2030 that explores a future landscape of manufacturing, understanding the main drivers and forces shaping it. After which EITM tried to imagine and anticipate how different the future might be from today?

To develop EITM’s future vision for 2030, we embraced imagination. Imagination requires a shift in mindsets, to let go of the ‘certain’ and to open oneself up to learning, relearning, and unlearning skills and ultimately reimagining a better story. So, in the last couple of months, we have courageously and collaboratively worked with EITM to align towards a shared vision of the future that is an invitation for dialogue and inspires leadership to consider how our decisions of today will impact generations of tomorrow.

‘Fixing Our Future’ is this positive, actionable, inclusive and irresistible vision for manufacturing in 2030. It presents an optimistic view of what manufacturing in Europe could become, a shared vision of hope for the present, but also a desired future for generations to come. A vision that can provoke thought among the leadership of EITM as well as inspire action and discussion among relevant stakeholders.

The Context in 2030.

What Europe and the world will be like in 2030 is unknown. Multiple futures are still open. The world today, however, is marked by rapid change. Of technologies, of climate, of certainties. More and more, we see old ‘certainties’ fading – which creates opportunities to reimagine. Sure, some things will still look the same in nine years, but we expect certain drivers to continue and even accelerate and change future landscapes. Values, behaviours, preferences, models, companies, people can change when the benefits outweigh the status quo.

Here is a glimpse of the driving forces that will shape how the world in 2030 might look …

Regenerative Everything

There is no doubt that the world in 2030 will be affected by climate change. How much and in what way is uncertain. But the climate emergency is real and will continue to impact and change everything. Think biodiversity loss and extreme weather events that are already affecting people’s daily lives and businesses. The world economy is expected to lose up to 18% of GDP from climate change if no action is taken. The climate crisis motivates and catalyses the desire for systemic change with organisations, governments, and people, not only to mitigate but also to adapt to the new climate realities.

In Europe, we will work and live in these new realities, where issues of drought, heat, shortage, safety and blackouts will become more and more normal. The term ‘regeneration’ has been picking up momentum in the last two years and seems promising for both health and the climate. Regeneration is the replenishing and restoring of what we have lost and building economies and communities that thrive, while allowing the planet to thrive too. We expect that regeneration across sectors and fields will be part of the conversation in 2030.

Ageing & Urbanised Europe

In most European countries, populations are getting older and population pyramids are rapidly changing with the working-age population shrinking considerably. With an ageing population that by 2060 will be 29.5% over 65-year-olds, manufacturing is facing the threat of losing a workforce who has meaningful knowledge. Furthermore, it might be more and more difficult to find people that can work in manufacturing, as there will be less working age people in Europe. Next to the impact of a shrinking population and the increase of elderly in society and work, we are also seeing a divide between rural and urban areas. The growing divide between life in the city and in the countryside will continue to create tensions. We see a rise of (young) people living in cities, looking for freedom of choice, (digital) connectedness and purpose. Young people’s choices and preferences are different. For example, the preference for public transport over owning a car. How can we overcome these differences in lifestyle choices, worldviews, and opportunities? How to address all of this in the future?

Post Truth Society

Not everyone’s reality is the same. Over the last couple of years, we have seen a rise in polarisation in Europe and we continue to see that people are reshaping how they live according to their own values and their own truth. The divide in society seems to be widening. Globalisation, migration, growing inequality, less security of existence, more conspiracy theories flourishing, and the ongoing coronavirus crisis seem to create divisions in Western societies. Large groups do not feel represented and thanks to social media, they can find one another more readily and easily. At the same time, radical right-wing influencers and politicians know how to reach and play them more and more easily.

Activist Movements Spearheading Change

Over the last two years, the number of protests have grown. These include protesting against the measures to combat the COVID-19 pandemic, the Hong Kong protests, the Capitol insurrection, Black Lives Matter protests and continuous actions against climate change. More and more people are getting frustrated, angry, sick of the blah, blah, blah, and simply tired of waiting. While Greta Thunberg started her school strike for the climate by herself, now we see that people are moving beyond purely individualistic actions as they demand collective action, systematic change and responsibility from brands and governments. People are upping their activist game, their demands, and their needs and feel that they can collectively move beyond pure sustainability towards degrowth, circularity and new values around inclusivity, justice and solidarity for the next generations.

Positive Side of Technology

Once upon a time, not so long ago, the world was disconnected, less complex and infinitely slower. Yet, this is no more. The future of manufacturing will only get faster, and the landscape will be driven by ever-accelerating technologies. Technology is racing forward and will continue to influence our lives well into the future. Yet, technology is both the problem and the solution. Or in the words of Melvin Kranzberg: “Technology is neither good nor bad; nor is it neutral.” In the end, what matters is the intention.

We can see the potential of innovative ideas with the intention to make the world better. Technologies can be used to make our world more sustainable. We can see huge opportunities for green technologies to have an impact and to fix some of the urgent issues we are currently dealing with. Investment in climate tech is continuing to show strong growth, whereas climate tech is not only creating a positive impact in today’s world but is also set to create billions in economic value.

When experts predict the future of work, they rely heavily on Artificial Intelligence (AI), machine learning, Industry 4.0 and automation. The conversation has been heavily dominated by a negative narrative of the notion of robots eager to take jobs.

Yet, automation is not new, nor is the fear of losing jobs. We have been here before. The massive factories and assembly lines of the Industrial Age transformed the workforce into mass producers. The Information Age introduced all this mass production to other parts of the world, with information and knowledge transforming the Western workforce into knowledge workers. Technology gave access to knowledge, people became smarter and felt more empowered, more connected, and more entrepreneurial. And that entrepreneurial spirit opens up a range of possibilities again.

So, if the intention is positive, the benefits of technology are undeniable:newfound opportunities can tackle environmental issues, speeding the adoption of the circular economy, improving healthcare, preventing fraud – and many, many more. But we have to be open to see the whole picture and keep an eye out for the unintended consequences. How will this play out in the European manufacturing sector? What choices will be made and how will people relate to technology in 2030?

Global Migration

Sudden and continuous climate emergencies displaced 40.5 million people (climate migrants) globally in 2020 and 216 million people could be forced to migrate within their own countries by 2050 due to climate change, according to the latest Groundswell report from the World Bank. And the number of climate migrants could be much higher since the report does not cover most high-income countries, Middle Eastern nations, small island states, or people migrating to new countries. With millions of people on the run, driven by climate change or political unrest, the world will experience potentially more geopolitical instability, leading to greater inequality.

If European nations manage to flip the narrative around, regarding newcomers, refugees, and migrants, we may possibly see the retreat of both populism and separatist movements as a result, and consequently foster changing attitudes and behaviours around the opportunity of newcomers in Europe.

The Future Of Europe

The future of Europe is unknown. But we have seen Europe is trying to lead and proactively set out policies and ambitions on complex challenges. We have seen the European Green Deal, where Europe wants to become the first climate-neutral continent by 2050. Think of ambitions such as to develop the new global norms on trustworthy AI, ethical guidelines on blockchain or Industry 5.0 as drivers for Europe’s transition to a more sustainable, human-centric, and resilient manufacturing industry. If Europe manages to set out a new ‘gold standard’ for the most complex, ‘wicked’ technological and social problems of our time, embracing European values and ideals, such as human rights and democracy, in its legal and regulatory framework, it could ensure that Europe is leading, and not following.

A New Paradigm Of Manufacturing.

How do you respond to the changing landscapes in 2030? When we close our eyes, what do we imagine manufacturing to look like in 2030? This chapter describes the essence, the building blocks for the 2030 Vision for Manufacturing. ‘Fix Our Future’ is a hopeful vision, setting out where we imagine manufacturing in Europe is going as we move towards 2030. Within this, three key themes have emerged:

- Ethics at the Core

- Do more with Less

- Connect the Interconnected

While these themes by no means represent the whole picture as we move towards 2030, they help focus our thinking as we set out to prepare the manufacturing sector to meet the needs of current generations without compromising the ability of future generations to meet their own needs.

Ethics at the core

The manufacturing sector is a big one, and the positive impact that it can create oin issues, such as the ongoing cliThe manufacturing sector is a big one, and the positive impact that it can create on issues, such as the ongoing climate crisis, gender equality, diversity, privacy, safety, health, amongst others, can become an inspiring guiding star for other industries that want to improve and strengthen their moral and ethical compass. As we move to 2030, we will start solving problems, not the symptoms.

With the increase of data-driven software and algorithmic decision-making, it is necessary to understand the technology in all its intentions: the positive and negative elements. For example, it is essential to understand the biases in AI technology and create transparency in data and algorithms as a prerequisite. We need to be able to think critically and act purposefully with the technology and systems offered. We should be much more concerned about the balance of technology and human rights, ethics, and morality. Future workspaces should be dominated by more humanised and mindful technologies that rely on ethical manufacturing and encourage lifelong learning. In the end, it is the moral identity that will be interwoven in the factories. It will be at the core of manufacturing and will impact leadership capacities for 2030. To navigate uncertainties, future leaders will not only have to upskill their moral skills, but also to embrace how to anticipate the future. We hope to see new leadership that mirrors the need for inclusion, empowerment, purposefulness, and ethical behaviours.

Do More With Less

Environmentally sustainable manufacturing has been on top of the list for manufacturers for a long time now. However, faced with wildfires, super storms, flash floods and extreme weather, people already feel that the climate emergency is at their door. The waiting is over. Action is simply too slow and too little. There is no alternative but to be smarter and do more with less. The only way to do this is to move from a human (and self-) centred approach in manufacturing to one where we aim to create a better alternative for both people and the planet.

From Ego to Eco

As we move towards 2030, a just and regenerative mindset will be the key to unlocking new ways of manufacturing, producing, consuming, working, and living. It sets out a new guiding principle: a manufacturing sector that sustains the well-being of all and the capacity of our natural world to replenish itself, while enabling long-term, broad-based prosperity with all manufacturers practising this ethos.

Connect the Interconnected

Within the manufacturing sector, skills and talent are at the top of conversation. Challenges such as retaining and attracting the right talent, with the right future profile and with the right skills are more pressing than ever. How to ensure an inclusive future where new generations of employees are inspired to shape the future of manufacturing? Sure, programmes to reskill and upskill the workforce is key, but our vision is to act as an enabler of interconnectedness.

As we move towards 2030, enabling and building collaboration will be key to survival. We see a world full of ideas and entrepreneurs out there that will bring in new relevant skillsets and profiles. A decentralised landscape of climate tech start-ups, material innovators, digital natives, eco-entrepreneurs that can be part of the innovation of manufacturers from the outside. Seen in other ecosystems of innovations, it is important that there is one hub that serves as the centre point of all these collaborations, enabling innovation and partnerships and connecting the interconnected.

Stories From The Future

The following fictional stories are snapshots of the future of manufacturing in Europe 2030. Stories can be used as a tool to catalyse change, to inspire, to shape new (mental) models and highlight new values. By telling and listening to these stories, the ‘Fixing Our Future’ vision can be brought to life. Stories to fire your imagination and think about possible “what-ifs”. Stories that tell us about the role of manufacturing (‘the Why’), the skills and workforce (‘the Who’), how things will be done (‘the How’) and future stories around the things that we will be making (‘the What’).

The stories have arisen from the work done in the co-creation processes, the research, the interviews and the dialogues with the EITM core and extended teams.

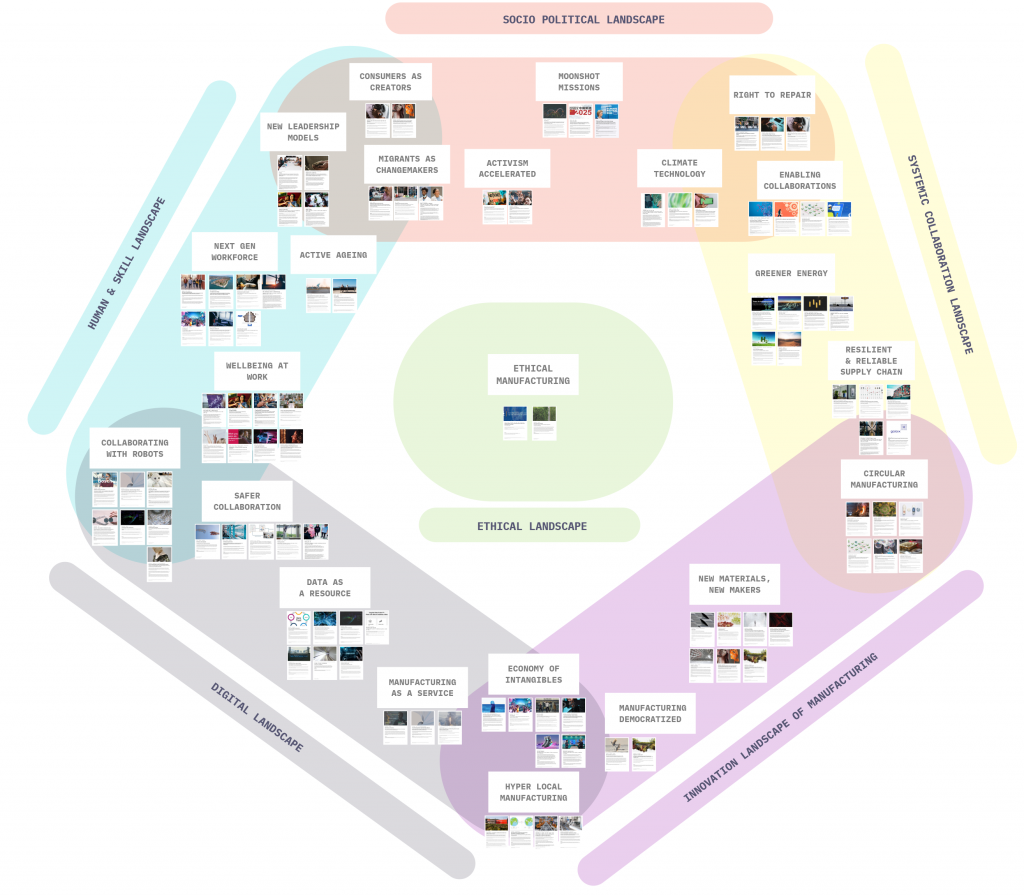

The Future Landscape of Manufacturing:

A Compass Of Orientation

A map of insights and signals shaping the Future of the Manufacturing sector.

Brussels, Belgium 2030.

Mary was looking out of the window after browsing the EITM website for the next conference coming up. The conference this year was focused on ‘Eco-Manufacturing and Responsible Leadership’. Mary smiled when she noticed the women that were speaking, most of whom she knew when they started as entrepreneurs 10 years ago, but now many of them run their own ‘Eco-Factories’. In 2024, the alarm bells went off, when Europe felt the heavy destruction of the ecological balance and reduction of species and natural habitats. Activists and advocacy groups brought legal challenges to national and EU courts, unsuccessfully. The New European Union realised that the Paris Agreement and its targets weren’t going to be met but did too little to really make a dent.

Therefore, EITM decided to act.

The politicians had talked about the topics for years, from environmentally sustainable manufacturing, more women in the workforce, enabling ecosystems of -innovation. But the pace of change was too slow. There was too much talk, and too little action. They had been solving the symptoms, not addressing the problems.

So realising after the first Covid-19 pandemic that the global supply chain issues weren’t a consequence of the ‘surging demand due to economies recovering from Covid’ – but are part of a much larger picture at tipping point, where global demand is outstripping what the Earth’s resources can supply. Climate change became EITM’s top priority to ensure a sustainable planet for future generations. There was no choice left now but to be smarter and do more with less.

Much has changed since then. Perhaps it was the positive energy unleashed when manufacturers realised that they could be more than a place of production, but rather, a connectivity ecosystem. And as a reaction, many young entrepreneurs started chasing new ideas, started experimenting, and became a part of their own ecosystems of innovation.

Mary saw that many traditional manufacturers jumped on board and embraced this new direction. Many businesses that were used to competing against each other – not only to have the best financial returns, but to have more richness, by moving around the world looking for cheaper resources and countries with less environmental restrictions, had to change course. Of course, this was only forced to be changed when things got upside down.

Businesses then focused on finding new collaborations, creating a business culture of respect for the local culture and the environment. From aiming to be the biggest car manufacturer in the sector to aiming to make mobility sustainable.

Before the EITM conference began, Mary had time to quickly drop in on the weekly meeting of her favourite project on ‘Responsible Digital Leadership’ in manufacturing. With the continuous digital transformation in manufacturing, more AI and virtual factories were popping up – and it became necessary to learn how to use technology and data responsibly to build trust so that technology is transparent, unbiased, and adapts to humans. Mary was surprised to see how well this project was working. Using VR to understand the many risks and ethical dilemmas related to the use of new technologies in manufacturing helped leadership to rethink ethics in their work. People at the meeting felt that what they were doing was good. A model that other people could learn from.

All of a sudden, Mary realised that the conference was about to start, and she hurried back just to have a couple of minutes left to prepare her talk.

This story of the future is based on the following related insights:

Ethical Manufacturing

Ethics has taken a centre stage, not only in the manufacturing sector, but across our society at large. Radical transparency enabled by technology and the impact of interconnected global events have forced companies, industries, governments and organisations to take ethics seriously. They have high demands for ethical actions and responsibility and consider this as the bare minimum expected behaviour. The manufacturing sector is a big sector, and the possible positive impact that it can create in issues such as the ongoing climate crisis, gender equality, diversity, privacy, safety, health and others, can become an inspiring guiding star for other industries that want to improve and strengthen their moral and ethical compass.

Points of Departure (Brain Triggers):

- What if manufacturing industry becomes the most ethical industry in the world?

- What if Europe sets the golden standard for ethical behaviour for manufacturing?

- What if “Ethical Taxes” are introduced in the future?

- What if technology will make it extremely easy for consumers and citizens to track and measure the “ethical footprint” of products and services in the near future?

Activism Accelerated

We have seen an acceleration of activist movements that demand change around the world. Where it once was something of the niches, the pressure of the pandemic has made it ever more necessary for civil action and activism to fix the political, economic and social challenges of the (post-)pandemic world. Tired of waiting, the next generations knows activism is not just something they do, but it really is part of who they are. From politics and media to the climate crisis, passion and first-hand experience drive this digital generation to ensure their voices are heard worldwide.

Key Dimensions

- Being ethical or moral will no longer be only something you talk about, but you will have to do it too and it will be on top of the agenda for future workforce to join an organization.

- Growing polarisation demands companies to stand up and speak out.

- Once raised awareness, it is about doing. More and more activists realise that you can only do so much. People moving from just individualistic frameworks as they demand collective action and responsibility.

- Expect a rise of all kinds of collective actions, standing together in strikes and even rebranding of the coolness of unions.

Points of Departure (Brain Triggers)

- How would the Patagonia of manufacturing look like?

- What are the new standards of ethics and morals for manufacturing?

- What are the possible protests that could happen in the manufacturing industry and how can you address these weak spots?

Moonshot Missions

The state is, and has been, our boldest and most valuable innovator, as stated by economist Mariana Mazzucato. In 2021 she published another important book “Mission Economy: A Moonshot Guide to Changing Capitalism; where she argues we need to think bigger and mobilise our resources in a way that is as bold as inspirational as the moon landing—this time to the most ‘wicked’ social problems of our time. This means changing government tools and culture, creating new markers of corporate governance, and ensuring that corporations, society, and the government to share a common goal. In the west, but also in other areas of the world we see the importance of governments and states setting standards, new visions and guidelines; Governmental to launch moonshot missions, to address our systemic wicked and intertwined challenges of the future.

Key Dimensions

- Real change doesn’t come in small bites, but more and more it becomes clear that it needs systemic changes to really make an impact.

- With governments creating moonshot visions it can reimagine futures of Europe to innovate and tackle real problems.

- If we can link the ambition articulated in moonshots such at the ‘EU Green New Deal’ to practice and the new ‘gold standard’ in Europe that embraces European values and ideals in its legal and regulatory framework, it ensures that Europe is leading, and not following.

- What could be the new models that can be developed to support this?

Points of Departure (Brain Triggers)

- What If European Values shifted and changed and how will this influence the Manufacturing sector?

- What if decentralised online communities will create the visions of the future, instead of governments and states?

- What if we could mobilize the political will and resources in a way that is as bold as inspirational to solve climate crisis and inequality?

- What if manufacturers are willing to call for systemic approaches to innovate and collaborate to step into the space what we think is possible to create real difference?

Enabling Collaborations

As more industries and sectors merge and become more interconnected and dependable to one another, the need for collaboration and communication across industries has become imperative. Being able to break the traditional silos of the manufacturing world and bridge and connect them with academia and the public sector can help promote better knowledge sharing, talent acquisition, and ensure a broader positive impact in society through sustainable innovations created in more holistic and systemic environments of cooperation.

Key Dimensions

- Addressing and facing future complex and interconnected challenges will only be done successful when we can build radical partnerships. For that, we need to bridge the various gaps between world views and perspectives, break silos and engage with people and communicate with a variety of disciplines to address value and change.

- Cross-company sharing and collaboration is needed for entire manufacturing systems.

- Collaboration is a super power of humans. How will Manufacturing use this?

- In order to work together, it will require to learn the new lingo, building tryst and understanding new ways of working will help you to built better collaborations for the future.

- Built open and flexible structures and cultures to invite new people and collaborators to the table of innovation.

Points of Departure (Brain Triggers)

- Who could be your most important partners in the future to collaborate with?

- What if regions and cities become key in building relationships?

- How can you foster current relationships but at the same time built new ones?

- What will be the common language and values that will be driving future collaborations?

- How to change culture within the manufactory business and which new facilitators could you bring in to make this happen?

Greener Energy

Future energy use, consumption and storage are just a few of the challenges within the manufacturing sector. With a greater level of automation and technological advancements applied in factories comes a higher need for energy. And new and greener energy suppliers and sources are high in demand. Although no clear cut winner solution is on the horizon, we do see that hydrogen has a high potential. However, the cost-effective aspect of hydrogen has to be addressed to really become an energy solution for a greener future.

Key Dimensions

- Greater automation of manufacturing results in an increase of energy intensity of processes. Therefore, new (sustainable) energy sources are crucial to meet these needs.

- Hydrogen seems to represent the green energy alternative, although further research is needed in order to improve its industrialisation potential.

- Perceiving nature around us as a valuable resource symbolises the change of minds and attitude of people towards nature.

Points of Departure (Brain Triggers)

- What if the reduce-reuse-recycle becomes the main rhetoric in manufacturing?

- How would green energy influence the energy supply? Would we need it even more because it was green?

- What if hydrogen reaches the scaleability phase? How will that disrupt the manufacturing landscape?

Circular Manufacturing

Circular economy is considered as one of the best strategies to combat the climate crisis. In a resource-constrained world, there is a noticeable trend of companies opting into the circular economy model. For manufacturers, this shift involves a move away from the “take, make, waste” linear economy and a step towards increased responsibility over the total lifecycle of a product and its environmental impact. It directs production and consumption into a circular model of repair and reuse, sharing and remanufacture of materials, plus recycling at all levels. It reduces the demand for raw materials, helps to extend product life, and reduces end-of-life cycle waste. It is obvious to say, but we say it anyway, that it is gaining momentum. At every level. From the EU publishing a Circular Economy Action plan in March 2020, to governments setting new targets, businesses embracing Circular Economy business models, SME jumping on the opportunity and closing loops as well as consumers embracing circular mindsets.

Key Dimensions

- Circular Economy is not only crucial to save our planet, it can create economic advantages for manufacturers as well. As changes accelerate and life gets more uncertain and complex, we see that the manufacturers who are actually experimenting and innovating in this space now will lead in the future. The ones that are pioneering and finding out how to be pro-active by researching flexible remanufacturing models, seeking to reduce waste in the production process and develop their own industry-specific solutions to a circular economy will be the ones who will stay relevant in the future.

- Circular Economy is good business, but it also could enrich the manufacturing sector with new, more human values and could create positivity and hope

- Circular Economy requires open collaboration for closed-loop systems. How to built trust, empathy and innovative problem-solving and do more with less together.

- Challenges and changes do not come alone, and we need to think how they can connect and enable each other for the good. Industry 4.0 is considered as one of the most important shifts within manufacturing, so how can we connect the dots? How can the trend of industry 4.0 enable greater productivity and improved use of resources within closed loop supply chains which include re-use and recovery.

- As manufacturers will be transitioning to the Circular Economy, processes need to be rethought, software to be updated, packaging made more sustainable and factories need to invest in retooling and retrofitting of equipment to run on clean energy sources.

Points of Departure (Brain Triggers)

- What if we could redesign factories today to fit a circular processes and a zero-waste world tomorrow?

- What if waste was never created in the first place?

- What if manufacturing in Europe sets the circular standard and will enable other parts of the world to collaborate to make more of less.

- What if the economy was built on using things rather than using them up?

- What if we would make our circular society of the future as irresistible as it is necessary?

New Leadership Models

At a time of crises, when the relationship between human and nature is being redefined, and mental wellbeing in the workplace is entering as a new paradigm of work, new leadership models and new strengths/skills are needed. Transformative feminist leaderships are pioneering new dynamics, proposing ‘power with others’ as an alternative concept to ‘power over others’. Another case of new model emerging is provided by regenerative leadership, clearly indicating the need to have a positive impact in the (planetary) system we participate in. It is time to give up privilege; while on the other hand, the manufacturing workforce is still deeply struggling with a gender-gap, in which more than two thirds of it is composed of men. Small and large manufacturing industries can move from being led to leading a new paradigm of work and inclusivity.

Key dimensions:

- Paul Hawken refers to changes and initiatives happening worldwide as a ‘planetary immune response’ at the crises we are facing. New leadership models can be considered a part of this! A growing portion of the workforce is not satisfied with historical leadership styles, and its drivers. New and more inclusive approaches are emerging, allowing for diverse new types of leadership.

- Within Manufacturing, issues with gender-gap can be even more profound than in other fields. New leadership models can find fertile ground for a deep and positive impact.

Points of Departure (Brain Triggers)

- What if Manufacturing became the leader field in new leadership models?

- How can new leadership models support in solving some of the challenges Manufacturing is facing?

Lodz, Poland 2030.

Joanna was polishing the last details and filters on her career storyboard that will give her access to meeting the factories that will fit her job preferences. It is how we used to date, back in the days, her father had said. Swiping left for the right purpose and lifestyle ‘fit’. Meaning that her values align with her future employer’s, but also indicating her growth potential for living a better quality of life. On her own terms. Because before accepting any job, she closely analyses her potential employers’ intentions, conditions, values and work-life boundaries. It has always been her childhood dream to work in manufacturing. To be part of the solution, to be able to make a positive impact and to be part of making things that last, not creating more of what belonged to the past.

Her father worked in leather manufacturing in Lodz for many years, up until 2022. The heavy industry with the old factories was no longer relevant and they remodelled the factories into an area where people could come to educate themselves and engage with communities that offered ‘share-their-skills’ sessions. The old factories basically became ‘factories for lifelong learning’. That is also where most of her education comes from. Where most of his work was focused on manual labour, her focus has been on intuitive technology, explainable AI and using her gaming experience to work with and within human technology.

Joanna’s first informal education had been focused on the actions that created impact to combat climate change and how to battle for an equal, just, and democratic society. Joanna’s generation grew up healthier, more creative and confident than their parents. Developing a digital mindset from the start and being raised with an ethical IQ, in a media landscape where activists such as Greta Thunberg were her role model, helped her build her aspirations and expectations for the future. She knew what she wanted. And what she wanted to do better.

Piotr was an HRR consultant (HR changed into Human Robots Resources a while ago) at ‘Gabriella’ in Lodz. He was staring out the window of the beautiful, naturally designed office, almost like his home environment within the office. It was great to see that the rewilding of the area had been successful and had created a landscape where nature was blooming and everyone could rest and enjoy peace and quiet, do sports, or meditate if they wanted to. In 2021, ‘Gabriella’ became a B-Corp company and started to manufacture a new range of tights made from recycled fishing nets and marine waste. Since then, business has been booming. And now they are recruiting for new roles in the company and factories.

Piotr is reading some of the text for the job posting, created by his unbiased algorithmic job advertisement generator:

“…our Lead Human Machine Teaming Manager is an empathic leader, supervising robots and she/he/they will operate at the intersection of people and robots and create seamless collaborations.…”

Piotr was very happy with that. He was hoping for applicants with strong data-science skills, digital literacy, and ethical capabilities when dealing with AI. Moreover, it is important that the candidate can help bridge data gaps and visualise big data, so that it is more easily explainable to the wider company. Scanning through the rest of the text, the work benefits and packages seemed in line with his vision. Well-being was key, from flexible hours working remotely, to lifestyle approaches that support parenting, caregiving, mental health and physical health. Added to this was also the possibility for lifelong learning if they wanted.

When Piotr became an HRR consultant, there were huge challenges with finding the right candidates with the right profiles in the manufacturing sector. Once they changed the narrative and reframed what and how to communicate, he started to notice a difference. The company started listening to the needs of future candidates with skills they didn’t even know they needed in the future. Piotr was thrilled to see that suddenly, they attracted a whole range of diverse candidates, true changemakers with high skills from everywhere in the world! Especially the entrepreneurial skills of climate migrants, which had been proven essential for Poland’s new industrial revolution and economic boom. He was proud that their approach had been a true inspiration to other sectors!

This story of the future is based on the following related insights:

Collaborating With Robots

Industry 4.0 has introduced the extensive use of cobots on the factory floor which caused implications for the entire manufacturing system. The level of collaboration between human and cyber-physical systems has developed profoundly, creating both opportunities and threats that need more and more attention. Suddenly, knowledge transfer and knowledge creation can be found in humans, systems and robots, requiring diverse and complex skills from the workforce. And even though the robots can take away mundane and repetitive tasks, a greater level of familiarity needs to be introduced.

Key Dimensions

- The level and sophistication of collaboration between human and cyber-physical systems developed profoundly.

- Knowledge transfer and knowledge creation is among all the partners (humans, systems and robots)

- We will see fewer people on the production line but people with different skillsets. A new role of the human emerging as the orchestrator and facilitator of the floor.

- With a continuous advancing of the level of automation, a higher understanding of cyber-physical systems is required from employees.

- Data is produced on a high level rising questions how to use it ethically within the systems.

Points of Departure (Brain Triggers)

- What will be the power dynamics of the relationship between human and robots in the manufacturing spaces?

- What if robots smoothen the workday of employees and they are making sure their wellbeing is taken care of too?

- What if robots could boost workers creativity and help them thinking out of the box whilst solving complex issues?

- What if the future factory would only need a small workforce of highly skilled managerial orchestrators?

Active Aging

With an ageing population that by 2060 will be composed by 29.5% of over 65, manufacturing is facing the threat of loosing a workforce who has meaningful knowledge. The problem can be addressed by a new understanding of the lifecycle of work; companies such as Michelin are offering to retired employees the possibility to join short term projects, where they can share their expertise with younger generations.

Key Dimensions

- Active ageing is defined by EU as ‘helping people stay in charge of their own lives for as long as possible as they age and, where possible, to contribute to the economy and society’ and this has been a priority for the Commission since 2012.

- In most of European countries, populations are getting older.

- The lifecycle of work should be redefined to address the needs of citizen and adapt to new structures.

Points of Departure (Brain Triggers)

- How will retirement programs look like in 10 years from now?

- What if companies could facilitate the collaboration and knowledge sharing among older and younger generations?

Consumers As Creators

The term ‘prosumer’ has been around for a while and is used in several ways. A prosumer could be a portmanteau of the words producer and consumer. In refers to consumers that not only consume, but also produce. For manufacturing it is interesting to see the rise of creators happening in material innovation (see ‘New Materials, New Makers’) that shifts from laboratory to creating impact in scale. Alongside this, we also see a continuous rise in sophistication and professionalisation of makers, Maker communities such as the Thingiverse community are offering serious alternatives at scale and show that they are beyond a community of hobbies. Lastly, we have seen is how consumers are becoming shareholders in the online eco-systems (the Metaverse) who previously only profited from them.

Key Dimensions

- The perception of value shifts when consumers become stakeholders, creators, makers and owners. We see more entrepreneurial, decentralised, equitable and user generated approaches.

- Where ownership and agency was once in the hands of the producer and makers, this trend influences other choices and decisions.

- Production can be done more in a community-run and crowdsourced, with open software, local and with circular processes.

- Entrepreneurship is in the blood of the new generations, just next to the drive for purpose and fairness. How will this impact future production and creations?

Points of Departure (Brain Triggers)

- What if creators become shareholders of manufactories?

- How would reimagine a manufactory processes where consumers become creators and stakeholders?

- What if all brands would be community-run and owned?

New Materials, New Makers

Driven by the climate crisis and changing consumer behaviour, we see traditional and new makers starting to develop and recovering materials, with nature as inspiration. A new wave of young entrepreneurs – fuelled with passion and purpose – and with digital platforms on their fingertips combining their knowledge and skillsets to develop better (bio-based) material alternatives to challenge the status quo. On the other hand, we see traditional manufacturers experimenting by starting to make their own materials to disrupt manufacturing as we know it.

Key Dimensions

- Nature will be a key inspiration for new material innovation in the future. Where it was once a niche, it will grow and will influence business models to address true sustainability.

- We see a new group of positive New Makers that will now enter the landscape of manufacturers and setting the norm for material innovation of the future.

- Besides shifting to more natural resources, some traditional materials will stay, such as steel etc, but driven by a growing pressure of sustainability, new factories and processes will be developed to make a positive contribution to the planet, instead of taking things aways from it.

Points of Departure (Brain Triggers)

- What if the manufacturing landscape will adopt a TikTok mindset and will start collaborating with these new material entrepreneurs in the future?

- What if mushrooms and tea bags become the new steel?

- What if manufacturers start growing their own materials in the future?

- What if we only use bio-materials and what does this mean for education and skills needed in manufacturing?

Next Gen Workforce

A new cohort of workers is entering the labour market. Raised in a highly digital world, this new generation has new values, new skills and different motivations than previous ones, forcing the manufacturing industry to rethink and redesign how to attract, retain and grow talent in order to remain attractive and relevant for those who want to make a career within the industry.

Key Dimensions

- The new generation is purpose and passion driven, they want their work to also make a positive dent in the world.

- The new generation values a healthy working environment, and a place where they feel that they can grow and expand in their career path.

- The new generation has new skills and competences enabled by their high digital literacy, gaming knowledge, and free and open attitude to technology. Lastly, the new generation posses a hybrid mindset.

Points of Departure (Brain Triggers)

- What if new skills (such as gaming, digitalisation, etc) become essential competencies in the future?

- How would you write a job posting for manufacturing for 2030?

- What if the manufacturing industry could reflect the values, skills and motivations of the younger generations?

- What if this new generation becomes the main driving force behind the industry and move from employees to employers, and run the industry? How would they design a factory?

- What if digital and “soft” skills are on top of the manufacturers agenda?

Migrants As Change Makers

With growing migrations to Europe, there is an urgent need to flip the narrative from seeing this as a problem to embracing the opportunity. With a talent shortage, we already see different organizations around the continent introducing innovative solutions to faciliate a welcoming start to a new culture and work environment. We have spotted innovative concepts in the tech sector and gastronomy to attract talent as well as upskilling refugees and migrants. What if these approaches can be an inspiration to other sectors, such as manufacturing?

Key Dimensions

- We can see a necessity to address the importance of inclusivity and diversity in modern societies, especially when looking into even more diverse futures;

- A potential and highly skilful workforce that tends to be excluded from the official career paths.

- Growing demand for employees in the manufacturing landscape, so potentially a great win-win for both sides.

Points of Departure (Brain Triggers)

- What if each company would rethink how they attract and communicate to new talent and facilitate exchange and the onboarding of new workers and migrants on a basis of curiosity and opportunity?

- What if diversity of employees was a status quo?

- What if Europe would open up manufacturing to a new workforce? How would that improve overall tolerance, social cohesion, but also productivity and collaboration at work?

Manufacturing Democratized

Smaller emerging players are revolutionizing the competitive dynamics within manufacturing. There is an evolving diversification around the business models used to enter the field(s). Multiple ways to find investments, together with the increasing use of collaborations between different actors of the supply chain define the entering barriers. On the other side, the accessibility to software decreases the costs and challenges the pre-existing infrastructure.

Key Dimensions

- Business Model innovation opens the field to small companies: they have higher accessibility to investments and facilitated path for growth and reaching customers.

- The accessibility to software is lowering entrance costs and increasing the entire landscape competition.

- Small players are challenging the giants – lower costs and lower entry barriers can create challenges for those who used to be solo players in the field.

Points of Departure (Brain Triggers)

- What if manufacturing had close-to-zero entry costs for new startups? How fast would innovations enter the field?

- What if the giants of manufacturing became the playing labs for small companies and employees to experiment and innovate? (already done in tech, not so much in manufacturing)

- What if the collaborative approach among “competitors” was the status quo?

New Leadership Models

At a time of crises, when the relationship between human and nature is being redefined, and mental wellbeing in the workplace is entering as a new paradigm of work, new leadership models and new strengths/skills are needed. Transformative feminist leaderships are pioneering new dynamics, proposing ‘power with others’ as an alternative concept to ‘power over others’. Another case of new model emerging is provided by regenerative leadership, clearly indicating the need to have a positive impact in the (planetary) system we participate in. It is time to give up privilege; while on the other hand, the manufacturing workforce is still deeply struggling with a gender-gap, in which more than two thirds of it is composed of men. Small and large manufacturing industries can move from being led to leading a new paradigm of work and inclusivity.

Key dimensions:

- Paul Hawken refers to changes and initiatives happening worldwide as a ‘planetary immune response’ at the crises we are facing. New leadership models can be considered a part of this! A growing portion of the workforce is not satisfied with historical leadership styles, and its drivers. New and more inclusive approaches are emerging, allowing for diverse new types of leadership.

- Within Manufacturing, issues with gender-gap can be even more profound than in other fields. New leadership models can find fertile ground for a deep and positive impact.

Points of Departure (Brain Triggers)

- What if Manufacturing became the leader field in new leadership models?

- How can new leadership models support in solving some of the challenges Manufacturing is facing?

Milan, Italy 2030.

Alberto was happy. All his life, he had been working at one of the biggest car factories in Bergamo, close to Milan. And today, his factory was still there and was setting a new standard for Europe and was doing better than ever. His factory had been one of the manufacturers who recognised early the importance of circular economy as a future strategy. It was not only crucial to save our planet, but it also had the potential to create huge economic advantages. So, Alberto was appointed ‘Chief Circularity Officer’ and as he had been exploring the opportunity for circularity in manufacturing since 2021, he was more than content that this obviously paid off now.

Today, the last coal plant in Milan closes. In 2025, The European Union initiated a programme for a ‘Just Transition’ and it took much effort, negotiation, huge sums of money and overcoming difficulties and barriers between several countries of Europe, to make it happen. And now, all the coal mines have been regenerated and restored environmentally, residents of those areas have been compensated and relentless efforts from climate activists have paid off. Nowhere in Europe is CO2 emitted from thermal coal, electricity is generated only from renewable energy sources and mainly from green hydrogen. All the old factories have been remodeled or demolished.

But Alberto’s factory was still there. Alberto was proud that his company had taken the risks by researching flexible remanufacturing models, seeking to reduce waste in the production process and developing their own industry-specific solutions to a future with circular economy as the main economy. In recent years, they re-thought processes, continuously updated software and invested in retooling and retrofitting equipment to run on clean energy sources. It was not easy, and he couldn’t have done it alone. He had been reaching out to emerging start-ups, collaborating, and offering them playgrounds to experiment and innovate. In the end, they managed to set up a decentralised closed loop system and put fairness, sustainability, and transparency in the centre of their supply chains with trusted partners who worked together, not apart.

What made him take action? While walking towards the factory floor, he remembers the exact moment when he started to make the ideas tangible. The failed ‘green’ reconstruction after the first global pandemic of our times laid it bare for him: there were not enough raw materials out there anymore for our constant thirst for more stuff. Extreme weather events will keep creating instability and by producing more electric vehicles in Europe could mean more poverty for the Global South. In other words, the idea of growth no longer worked, he realised. Even if there would be a full transition into a green society, these changes would only have limited success in maintaining the world as we knew it.

They needed to be smarter, do more with less, create shorter supply chains through localisation and create less dependency in a world full of volatility. He believed that investing and learning from green technologies with circular approaches would be the company’s best bet to stay competitive on a healthy planet for future generations to come.

This story of the future is based on the following related insights:

Data As A Resource

The manufacturing sector is increasingly starting to collaborate across hyperconnected value networks in order to increase productivity, develop new products and improve customer experiences which will have a positive impact on society and the environment. Data is, and will be, the lifeblood of the new digital factory, and the industry will need to start understanding and treating data as a valuable resource by utilising a large variety of data and analytics applications and by requiring new skill sets to ensure the successful transformation of manufacturing processes and supply systems. At the same time, the manufacturing sector should ensure that data doesn’t become a liability. Challenge will be to ensure that the data is handled with care and of good quality.

Points of Departure (Brain Triggers)

- What if we enter a future, where we no longer can provide the transparency needed in data and our technical systems become “black boxes” that produce insight without explanation?

- What if the manufactory sector will experiment with hackathons to ensure the ethical and human aspects are ensured in future innovations?

- Who will own all the data in the future? What if consumers become data owners, what does this mean for future manufactory business models?

Enabling Collaborations

As more industries and sectors merge and become more interconnected and dependable to one another, the need for collaboration and communication across industries has become imperative. Being able to break the traditional silos of the manufacturing world and bridge and connect them with academia and the public sector can help promote better knowledge sharing, talent acquisition, and ensure a broader positive impact in society through sustainable innovations created in more holistic and systemic environments of cooperation.

Key Dimensions

- Addressing and facing future complex and interconnected challenges will only be done successful when we can build radical partnerships. For that, we need to bridge the various gaps between world views and perspectives, break silos and engage with people and communicate with a variety of disciplines to address value and change.

- Cross-company sharing and collaboration is needed for entire manufacturing systems.

- Collaboration is a super power of humans. How will Manufacturing use this?

- In order to work together, it will require to learn the new lingo, building tryst and understanding new ways of working will help you to built better collaborations for the future.

- Built open and flexible structures and cultures to invite new people and collaborators to the table of innovation.

Points of Departure (Brain Triggers)

- Who could be your most important partners in the future to collaborate with?

- What if regions and cities become key in building relationships?

- How can you foster current relationships but at the same time built new ones?

- What will be the common language and values that will be driving future collaborations?

- How to change culture within the manufactory business and which new facilitators could you bring in to make this happen?

Wellbeing At Work

How we work, where we work, what we expect of work and our wellbeing at work and our working conditions have been rapidly changing over the last couple of years. We see that the next generation workforce will expect more flexibility: flexible work hours, flexible locations and activities that contribute to a better planet.

They expect working conditions that fits their wellbeing. The next generation thinks differently about ‘fixed certainties’ around power, diversity, social causes, privilege and the traditional male / female divide. As such, they will vocally challenge the orthodoxy and force society to rethink traditional work patterns and role models. Lastly, they will be more critical of every company’s business practices, and before accepting a job they will closely analyse their potential employers’ intentions, conditions, values and work-life boundaries.

Key Dimensions

- How future companies and manufacturers intepretate future ideas around workforce wellbeing’ into practice, will impact how eager future generations will want to work for you.

- Manufacturers should redefine work packages and ways of working to address new expectation of wellbeing of the future generations and create a more inclusive workforce, where personal preferences are acknowledged and taking into account.

- Wellbeing at work is about the physical and digital workspace. The need for mental wellbeing is a trend will continue to increase in the workplace, forcing manufacturing to redesign workflows in order to reduce mental stress.

Points of Departure (Brain Triggers)

- What if children would dream of working in manufacturing?

- What if factories become places where happiness and joy are measured instead of productivity and profit?

- What if manufacturers will design their work packages and benefits where flexibility and personal preferences are leading?

- What if every manufacturer has wellbeing approaches to support parenting, caregiving, mental health and physical health?

- What if manufacturers put wellbeing central?

- What if factories will become the new lifestyle centres where people can improve their wellbeing and happiness?

Climate Technology

More and more businesses know that green is the way forward. However, that doesn’t mean that it always on top of their priority list, especially when resources are tight. We see that SME’s (small medium-size enterprises) within the manufacturing sector are challenged. Even though they would like to implement more greener, circular and better solutions, they are constrained to making sure that economic value is created first and foremost.

Key Dimensions

- How to be green? Green solutions are available but there is a huge opportunity to make them available to SME’s and also to communicate the economic value for SME’s for being green.

- It is important to support SME’s in green solutions by giving access to infrastructure and commercialisation.

- The green mindset is not a priority, but rather an additional benefit in case of contributing to lower costs.

Points of Departure (Brain Triggers)

- What if a new business model of manufacturing promoted greener solutions before profit?

- What if the economic incentive was placed by social and environmental ones?

- What if public and private fundings supported and promoted solely green manufacturing?

Resilient and Reliable Supply Chain

Consumers are increasingly aware of the environmental and humanitarian issues and demand full transparency throughout the whole supply chain. With this push from consumers to honesty and business ethics, connecting the dots of the whole system and providing solutions that are real and true become crucial. It will ensure that consumers see what is happening throughout the supply chain, it will also tackle ‘greenwash’ and bring much-needed transparency in every industry. Furthermore, manufacturing needs to adapt to a supply chain where shortage might be the norm.

Key Dimensions

- It might be good for manufacturing to start rethinking their supply chain in an economy where shortage, disturbance and volatility are the norm. Can you rethink your business models to create less dependency and more guarantee in these circumstances?

- Manufacturing can create excellence and consumer trust, when they offer consumer transparency throughout the supply chain, ensuring them that they walk the talk.

Points of Departure (Brain Triggers)

- What if we develop, design and test processes and models to create a supply chain that is built for efficiency, resilience and transparency?

- What if manufacturers would built capacities and skills for a world where we need decision making given high uncertainty and volatility?

- What if we centre fairness, sustainability and transparency in the centre of our future supply chains?

- How do we ensure that when innovating our supply chains with new technologies, old patterns will not be reproduced?

Collaborating With Robots

Industry 4.0 has introduced the extensive use of cobots on the factory floor which caused implications for the entire manufacturing system. The level of collaboration between human and cyber-physical systems has developed profoundly, creating both opportunities and threats that need more and more attention. Suddenly, knowledge transfer and knowledge creation can be found in humans, systems and robots, requiring diverse and complex skills from the workforce. And even though the robots can take away mundane and repetitive tasks, a greater level of familiarity needs to be introduced.

Key Dimensions

- The level and sophistication of collaboration between human and cyber-physical systems developed profoundly.

- Knowledge transfer and knowledge creation is among all the partners (humans, systems and robots)

- We will see fewer people on the production line but people with different skillsets. A new role of the human emerging as the orchestrator and facilitator of the floor.

- With a continuous advancing of the level of automation, a higher understanding of cyber-physical systems is required from employees.

- Data is produced on a high level rising questions how to use it ethically within the systems.

Points of Departure (Brain Triggers)

- What will be the power dynamics of the relationship between human and robots in the manufacturing spaces?

- What if robots smoothen the workday of employees and they are making sure their wellbeing is taken care of too?

- What if robots could boost workers creativity and help them thinking out of the box whilst solving complex issues?

- What if the future factory would only need a small workforce of highly skilled managerial orchestrators?

Manufacturing As A Service

The democratization of manufacturing technologies and processes is making possible to grant access to cutting edge software and hardware to players that only a few years ago couldn’t enter the manufacturing sector without massive investments in R&D and facilities. We see big players providing manufacturing flexible and accessible platforms and services for smaller productions, as the demand for state of the art technology is increasing among small and medium size enterprises. As the relevance of software increases in the manufacturing process, it will be possible that more and more small players can have access to design and build new products in smaller scales of production, increasing innovation and creating a more diverse offer to consumers.

Key Dimensions

- Some say that services, not products, are the future of manufacturing. With more and more smart products being manufactured, we see the concept of product as a service on the rise that allow users to modify, upgrade and download features and updates for their own customisation. This will reshape how we organise flexible factories and what skillsets we are looking for in our future workforce.

- Manufacturing could expect more focus on recurring services which will establish a deputing relationship between manufacturer and customer.

- With more flexibility in services, there might be opportunities for new subscription services that can be adapted to immediate needs from the workforce and the users.

Points of Departure (Brain Triggers)

- What does this mean for the workforce within manufacturing, where there is need for highly skilled experts or service designers collaborating with digital technologies and tools?

- Imagine a world where manufacturing can be offered in modular services that can be mixed and matched just like Lego bricks.

Safer Collaboration

Industry 4.0 has increased the need and amount of (human) robots within the manufacturing process with a higher level of sophistication. With this development there is more collaboration between humans and robots. It raises awareness and issues around safety, risk, fears, and hesitance for employees working with and around them. Furthermore, employees need a higher level of assurance that their roles won’t become redundant in the upcoming years.

Key Dimensions

- It will be more important to support employees with the challenges of closer human collaboration in future manufacturing systems. Ensure to work safely with robots will be key.

- Communicate and understand which tasks fit robots and what the roles in the future will and can be for humans and robots.

- In the future, it is even more important to make sure that employees feel safe and accustomed to collaborating with robots.

- AI solutions can help with facilitation of a smoother transition in the collaboration between humans and cyber-physical systems.

- Designing robots with social interaction in mind is becoming increasingly important.How will this impact the feeling of safety in manufacturing?

Points of Departure (Brain Triggers)

- What if humans collaborate with robots freely?

- What if safety issues didn’t pose any threat to humans?

- What if your robot ‘gets you?

Right To Repair

Driven by the Circular Economy, the ‘right-to-repair’ movement and eco-design regulations are more and more defining standards. The EU is restricting products designed to be unfixable, forcing companies to change their ways of manufacturing and giving people access to repair. Consumer mindset is altering, craftsmanship revalued and celebrated and all of this is putting pressure on manufacturers to be more open how to repair their goods and make it easier for third parties to help them in the process.

Key Dimensions

- The demand to repair has been out there for a while and it changes how manufacturers are designing and planning their processes as well as what role they could play in the future of manufacturing.

- We will see an ongoing push from consumers and regulators for the right to repair and brand responding to it. Though there are barriers ahead, but with a consumer mindset altered, we expect we have not seen the end of it.

- There is a lot of opportunity to better the ‘post purchase’ consumer experience. It has gone from beyond alleviating pain points, to encouraging consumers to build a long-term, sustainable relationship with the products they buy.

- It becomes easier for more people to join the repair movement.

- For manufacturing it is interesting to reflect on their position in an interconnected repair ecosystem. An open system that, through regulations, can work better and better together and will guarantee quality and safety.

Points of Departure (Brain Triggers)

- What if repairability would be part of the ‘Universal Rights’ in all products manufactured in Europe?

- How can a repair mindset be even more ingrained in schools and with retailers?

- What if we would start repairing in the Metaverse? How would this look like?

- How can we design and adapt products for multiple users as well as normalise the use of repaired products?

Consumers As Creators

The term ‘prosumer’ has been around for a while and is used in several ways. A prosumer could be a portmanteau of the words producer and consumer. In refers to consumers that not only consume, but also produce. For manufacturing it is interesting to see the rise of creators happening in material innovation (see ‘New Materials, New Makers’) that shifts from laboratory to creating impact in scale. Alongside this, we also see a continuous rise in sophistication and professionalisation of makers, Maker communities such as the Thingiverse community are offering serious alternatives at scale and show that they are beyond a community of hobbies. Lastly, we have seen is how consumers are becoming shareholders in the online eco-systems (the Metaverse) who previously only profited from them.

Key Dimensions

- The perception of value shifts when consumers become stakeholders, creators, makers and owners. We see more entrepreneurial, decentralised, equitable and user generated approaches.

- Where ownership and agency was once in the hands of the producer and makers, this trend influences other choices and decisions.

- Production can be done more in a community-run and crowdsourced, with open software, local and with circular processes.

- Entrepreneurship is in the blood of the new generations, just next to the drive for purpose and fairness. How will this impact future production and creations?

Points of Departure (Brain Triggers)

- What if creators become shareholders of manufactories?

- How would reimagine a manufactory processes where consumers become creators and stakeholders?

- What if all brands would be community-run and owned?

Circular Manufacturing

Circular economy is considered as one of the best strategies to combat the climate crisis. In a resource-constrained world, there is a noticeable trend of companies opting into the circular economy model. For manufacturers, this shift involves a move away from the “take, make, waste” linear economy and a step towards increased responsibility over the total lifecycle of a product and its environmental impact. It directs production and consumption into a circular model of repair and reuse, sharing and remanufacture of materials, plus recycling at all levels. It reduces the demand for raw materials, helps to extend product life, and reduces end-of-life cycle waste. It is obvious to say, but we say it anyway, that it is gaining momentum. At every level. From the EU publishing a Circular Economy Action plan in March 2020, to governments setting new targets, businesses embracing Circular Economy business models, SME jumping on the opportunity and closing loops as well as consumers embracing circular mindsets.

Key Dimensions

- Circular Economy is not only crucial to save our planet, it can create economic advantages for manufacturers as well. As changes accelerate and life gets more uncertain and complex, we see that the manufacturers who are actually experimenting and innovating in this space now will lead in the future. The ones that are pioneering and finding out how to be pro-active by researching flexible remanufacturing models, seeking to reduce waste in the production process and develop their own industry-specific solutions to a circular economy will be the ones who will stay relevant in the future.

- Circular Economy is good business, but it also could enrich the manufacturing sector with new, more human values and could create positivity and hope

- Circular Economy requires open collaboration for closed-loop systems. How to built trust, empathy and innovative problem-solving and do more with less together.

- Challenges and changes do not come alone, and we need to think how they can connect and enable each other for the good. Industry 4.0 is considered as one of the most important shifts within manufacturing, so how can we connect the dots? How can the trend of industry 4.0 enable greater productivity and improved use of resources within closed loop supply chains which include re-use and recovery.

- As manufacturers will be transitioning to the Circular Economy, processes need to be rethought, software to be updated, packaging made more sustainable and factories need to invest in retooling and retrofitting of equipment to run on clean energy sources.

Points of Departure (Brain Triggers)

- What if we could redesign factories today to fit a circular processes and a zero-waste world tomorrow?

- What if waste was never created in the first place?

- What if manufacturing in Europe sets the circular standard and will enable other parts of the world to collaborate to make more of less.

- What if the economy was built on using things rather than using them up?

- What if we would make our circular society of the future as irresistible as it is necessary?

Hyper Local Manufacturing

Increasing requirements and consumer awareness around transparency in supply chain are raising questions around how flexibility can be translated into manufacturing. With the shorting of the supply chain, various systems are being explored. In order to reduce the transportation of materials, sustainable systems could promote a global network for design and development, with a local product execution.On the other hand, post-ownership economy is providing alternatives to the purchase of machines, promoting flexibility within infrastructure collaboration.

Key Dimensions

- There are new emerging paradigms when it comes to production. Local production became mainstream within foods for example. However, it might be more complex to translate that into heavy manufacturing. One proposed approach is to provide a global take on design and product development, while focusing on producing local.

- Post-ownership economy can provide a more sustainable option for businesses, offering a positive influence on the budget and on the amount of machines that need to be used.

Points of Departure (Brain Triggers)

- Can local production become a true competitive advantage of manufacturing?

- What if co-owned machineries become the new norm of production within manufacturing?

Manufacturing Democratized

Smaller emerging players are revolutionizing the competitive dynamics within manufacturing. There is an evolving diversification around the business models used to enter the field(s). Multiple ways to find investments, together with the increasing use of collaborations between different actors of the supply chain define the entering barriers. On the other side, the accessibility to software decreases the costs and challenges the pre-existing infrastructure.

Key Dimensions

- Business Model innovation opens the field to small companies: they have higher accessibility to investments and facilitated path for growth and reaching customers.

- The accessibility to software is lowering entrance costs and increasing the entire landscape competition.

- Small players are challenging the giants – lower costs and lower entry barriers can create challenges for those who used to be solo players in the field.

Points of Departure (Brain Triggers)

- What if manufacturing had close-to-zero entry costs for new startups? How fast would innovations enter the field?

- What if the giants of manufacturing became the playing labs for small companies and employees to experiment and innovate? (already done in tech, not so much in manufacturing)

- What if the collaborative approach among “competitors” was the status quo?

Greener

Energy

Future energy use, consumption and storage are just a few of the challenges within the manufacturing sector. With a greater level of automation and technological advancements applied in factories comes a higher need for energy. And new and greener energy suppliers and sources are high in demand. Although no clear cut winner solution is on the horizon, we do see that hydrogen has a high potential. However, the cost-effective aspect of hydrogen has to be addressed to really become an energy solution for a greener future.

Key Dimensions

- Greater automation of manufacturing results in an increase of energy intensity of processes. Therefore, new (sustainable) energy sources are crucial to meet these needs.

- Hydrogen seems to represent the green energy alternative, although further research is needed in order to improve its industrialisation potential.

- Perceiving nature around us as a valuable resource symbolises the change of minds and attitude of people towards nature.

Points of Departure (Brain Triggers)

- What if the reduce-reuse-recycle becomes the main rhetoric in manufacturing?

- How would green energy influence the energy supply? Would we need it even more because it was green?

- What if hydrogen reaches the scaleability phase? How will that disrupt the manufacturing landscape?

Amsterdam, The Netherlands 2030.